Hull form is determined by principal dimensions, hull form coefficients representing the geometric characteristics, shape and profile of bow and stern, longitudinal and vertical distribution of displacement, cross section curve. Hull form must be designed with clear understanding not only qualitative impacts but also quantitative impacts on ship performance. We fully understand the parameters and accurately estimate the speed you want to achieve in order to accomplish the optimum results. During the initial design, design concepts should be developed considering the relationship between the following parts of the hull and the major fluid dynamic performance.

Provide of initial design for writing basic specification and sales

Optimum performance for various ship types, specification and design of aluminum ship

Optimal structure determination and equipment layout design based on basic design

Production design according to production site characteristics

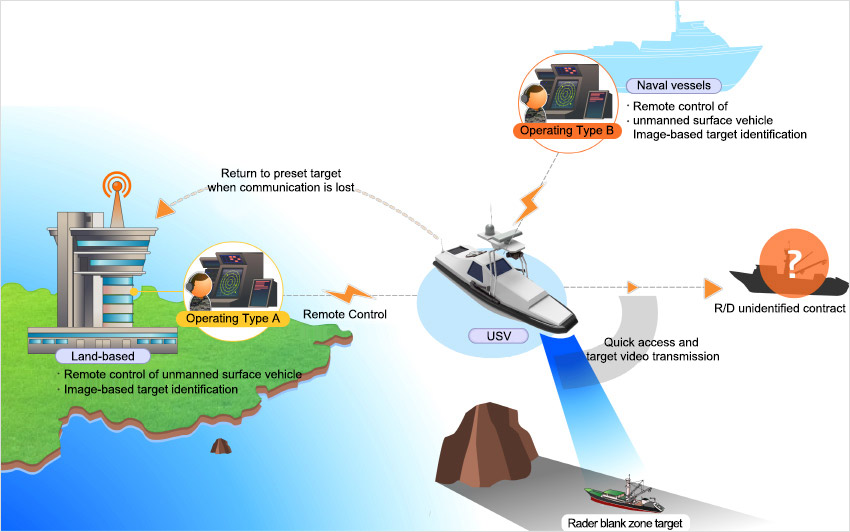

Digitalization and Maritime Autonomous Surface Ships(MASS) are navigation satellite(GPS), infrared camera, and various sensors related navigation to enhance safety during ship operation. Major equipment and technologies are as follows.

- High-performance shipboard control system(Maritime Automous high performance shipboard bridge) : Operate the ship during Maritime Automous, optimize energy efficiency, prevent collision after recognizing the surrounding situation, and provide safety support

- Maritime Automous engine room : engine status, energy efficiency monitoring and data transfer to the ground control center

- High-performance detection system(Infrared camera, GPS, navigation system, etc.) : Collects and analyes various information around a ship that can not be seen by the human. At the ground control center, crew members monitor and control ship operations around the world. And Interactive smart screen, voice recognition service, hologram and surveillance drones to monitor situations inside and outside the vessel

HAEMIN HEAVY INDUSTRIES CO., LTD. tel: +82 – 51 – 266-7968 fax:+82 – 51 – 266-7969

29, Noksansaneopjung-ro, Gangseo-gu, Busan, Republic of Korea CEO : Hyung Suk, Oh